How We Operate

Our Project Approach

Our structured approach to mechanical engineering and process automation follows five key stages:

1. Assessment & Understanding

We begin each project with a thorough analysis of your operations, identifying specific challenges and opportunities for improvement. This critical foundation ensures our solutions address root causes rather than symptoms, establishing clear objectives for safety, efficiency, and cost parameters.

2. Concept Development

Based on your requirements, we develop and evaluate multiple solution concepts, presenting you with options and associated cost-benefit analyses. This collaborative process ensures the selected approach balances innovation with practical implementability, perfectly aligned with your operational constraints.

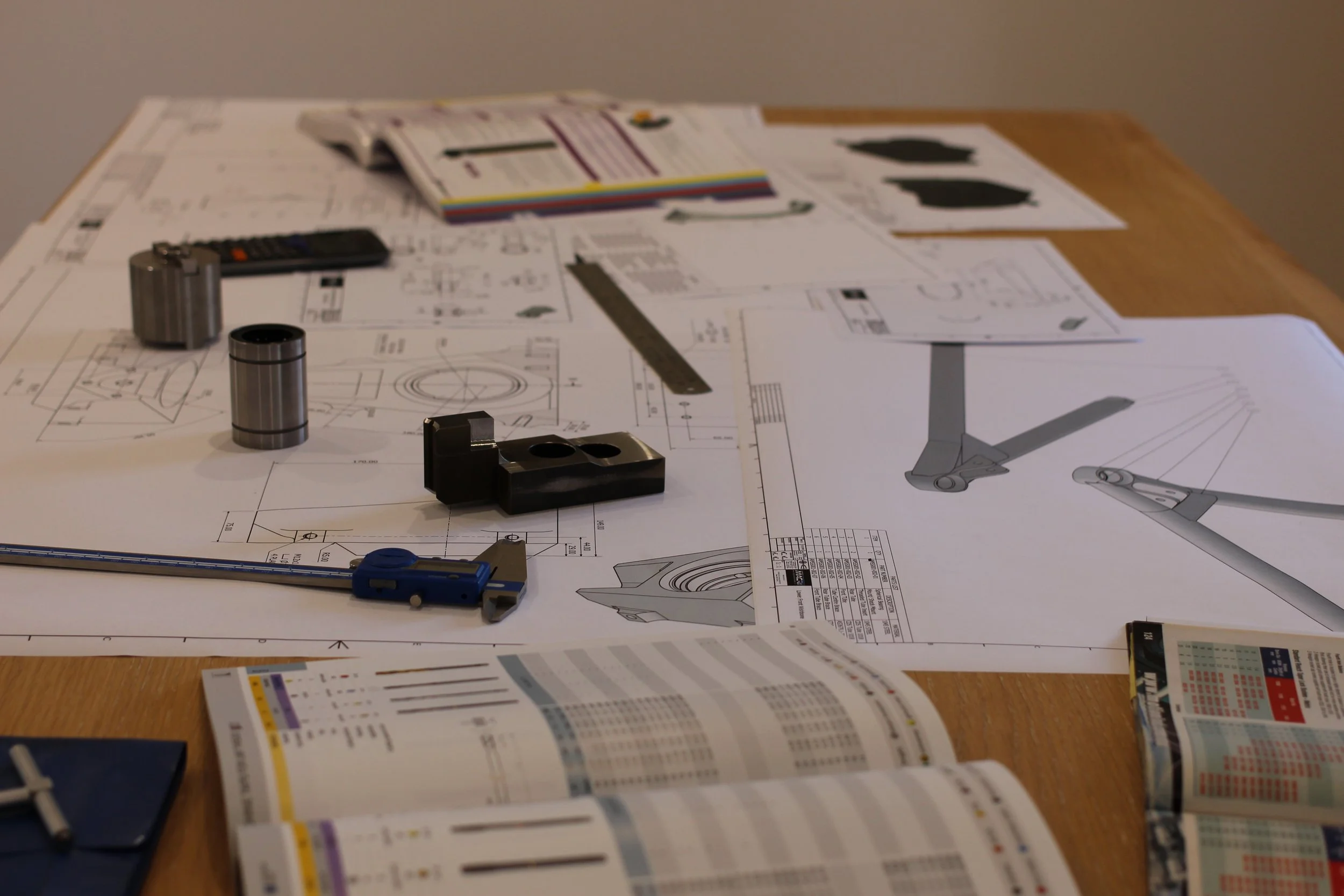

3. Design & Engineering

Our technical team creates detailed CAD models, comprehensive documentation, and when needed, performs structural analysis to validate performance. Every design element is optimised for functionality, durability, and cost-effectiveness, preventing manufacturing issues before they occur.

4. Manufacturing Coordination

We work with trusted Sydney and NSW manufacturing partners to translate designs into physical components. Our oversight ensures specifications are accurately implemented, maintaining quality control throughout the production process and addressing any challenges that arise.

5. Implementation & Validation

The final phase involves installation support, comprehensive testing, and performance verification under actual operating conditions. Our thorough validation confirms your solution delivers the expected improvements and fully addresses your original manufacturing challenges.

Why This Process Works

This systematic approach delivers consistent results by:

Common Questions

-

Focused mechanical designs typically require 2-4 weeks, while comprehensive automation projects may take 2-8 months from concept to implementation. We provide detailed timeline estimates during our initial assessment.

-

We need to understand your current manufacturing situation, challenges, and objectives. Our assessment can gather necessary information through direct observation and targeted discussions with your team.

-

Your involvement is most intensive during the initial assessment and concept review phases. Regular review sessions ensure the solution remains aligned with your requirements, with communication frequency tailored to your availability.

-

Our process accommodates reasonable changes, particularly during early phases. For significant scope changes after design approval, we discuss timeline and budget implications transparently.

-

We coordinate with trusted manufacturing partners appropriate for your specific project requirements while maintaining technical oversight to ensure quality and specification compliance.

-

After validation, we conduct a final review to verify all requirements have been met. We remain available for technical support, with many clients engaging us for additional projects as their operations evolve.

-

Engineering solutions are tailored to your specific requirements, so costs vary based on project complexity, scope, and timeline. Rather than providing general estimates that might not apply to your unique situation, we prefer to understand your specific needs first. Please contact us to discuss your project, and we will provide appropriate budget guidance based on your actual requirements.

Start Your Project

Ready to discuss how our proven process can address your manufacturing challenges?