Industrial Manufacturing Automation

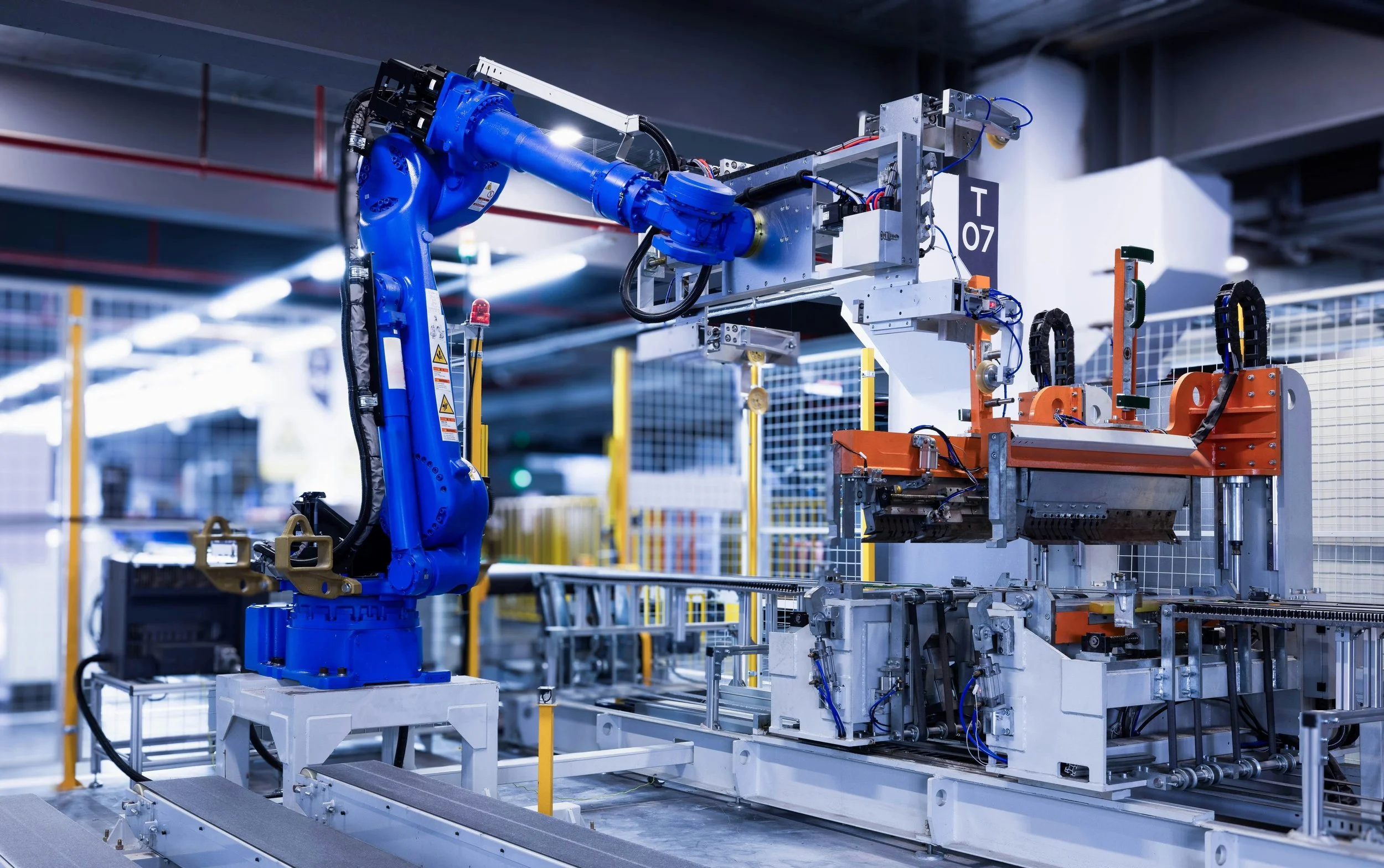

Macri Engineering specialises in transforming manual manufacturing operations into efficient automated systems for Australian industry.

Our manufacturing automation approach helps companies transition from labour-intensive manual handling toward streamlined, automated solutions that deliver measurable performance improvements.

We focus on engineering systems that enhance operational efficiency, increase production throughput, reduce manufacturing costs, and improve workplace safety across diverse industrial environments.

What We Help With

-

Manual to Automated Process Conversion

Transform labour-intensive operations into efficient automated systems. Our solutions typically reduce manual handling requirements by 50-80% while improving consistency and output quality.

-

Production Bottleneck Analysis & Solutions

Identify and eliminate constraints limiting your manufacturing capacity. We locate critical bottlenecks and implement targeted solutions that increase overall production throughput by 15-40%

-

Throughput & Efficiency Improvements

Enhance production capacity and resource utilisation across operations. Our automation systems optimise cycle times and reduce downtime, delivering measurable improvements to manufacturing output.

-

Safety Enhancement Through Automation

Reduce workplace hazards by automating dangerous or ergonomically challenging tasks. Our solutions improve compliance with ISO safety standards while enhancing operational performance.

-

Manufacturing Cost Reduction

Decrease production costs through strategic process automation. We target areas where automation delivers significant savings through reduced labour costs, decreased material waste, and improved quality control.

-

Process Streamlining & Optimisation

Eliminate unnecessary steps and maximise workflow productivity. Our comprehensive approach optimises entire process sequences, not just individual operations, for maximum efficiency gains.

Our Automation Process

1. Understanding Requirements

We analyse your specific operational needs, constraints, and objectives to establish a solid foundation for the design process.

2. Concept Development

Our engineering team develops initial solutions and verifies feasibility through preliminary analysis, ensuring alignment with your requirements.

3. Technical Documentation

We create comprehensive design specifications, including detailed CAD models, drawings, and manufacturing parameters.

4. Manufacturing Coordination

We work with production partners to ensure designs translate effectively into physical components, addressing any challenges that arise.

Ideal For:

Our industrial manufacturing automation services deliver particular value for:

— Manufacturers seeking efficiency improvements through specialised tools and equipment

— Companies with unique production requirements not met by standard machinery options

— Businesses looking to enhance or modify existing mechanical systems for better performance

— Industries requiring precise technical documentation for manufacturing or compliance purposes

Whether you need a complete custom solution or targeted improvements to existing systems, our mechanical engineering expertise helps transform operational challenges into competitive advantages.